We are constantly reminded by those who have come across our patented belt design concept for the outboard motor, as to how clever the whole design is. We call it a recombination innovation – meaning using best in class standalone innovations that have been well developed and combining it to create a highly innovative product that the customer wants.

Content from our commercial partners

Content from our commercial partners

OXE Marine AB

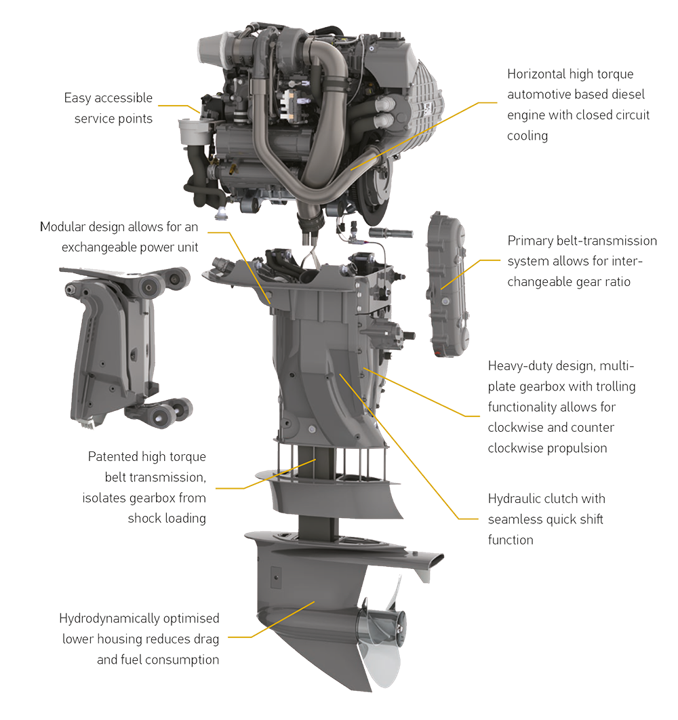

We are constantly reminded by those who have come across our patented belt design concept for the outboard motor, as to how clever the whole design is. We call it a recombination innovation – meaning using best in class standalone innovations that have been well developed and combining it to create a highly innovative product that the customer wants. OXE Marine´s modular outboard design does away with the conventional outboard bespoke vertical mounted engine, drive shaft and bevel gears and instead uses the state-of-the-art automotive engine, which is horizontally mounted powered to an industrial gear box with hydraulic multi-friction plate clutch (used by inboard marine engines) via off the shelf industrial carbon fibre belts. The true innovation in our concept is the lower leg design, which will allow huge level of power and torque to be delivered to the propeller - this can be powered by any motor, such as the internal combustion engine or an electric motor. We have come a long way since we began production of the world’s first high powered diesel outboard, in 2016 with well over 500 engines currently in operation worldwide we have just started delivery of our latest model, the OXE300.

OXE Diesel

The powerhead on all OXE Diesel has been adopted from the automotive industry. The horizontally mounted engine reduces wear and improves heat dissipation.

The power is transferred to the gearbox through the primary chain which opens up for high speed or high torque setting. From the gearbox, a carbon fiber belt transfers the power directly to the propeller shaft, eliminating the need for a conventional bevel gears or dog clutches.

The patented OXE Diesel system is a revolution to the outboard engine markets dependence on a traditional outboard drive system, eliminating the need for antiquated, vulnerable and inefficient dog clutch and bevel gear systems. Not only does the robust design of the OXE Diesel facilitate the high torque transfer of a diesel engine where conventional drive systems could fail, the OXE Diesel presents the end-user with a product specifically built for arduous working conditions.

By using a modular design, the OXE has been built from the ground up with proven conventional technology.

All parts are easy to access and can be changed without having to disassemble the whole unit. Each part has its place.

OXE300

OXE 300 also opens up the governmental market as it delivers the high power to weight ratio demanded by military operators, who require a viable alternative to petrol to comply with NATO’s single fuel policy which is driving the transition from petrol to diesel.

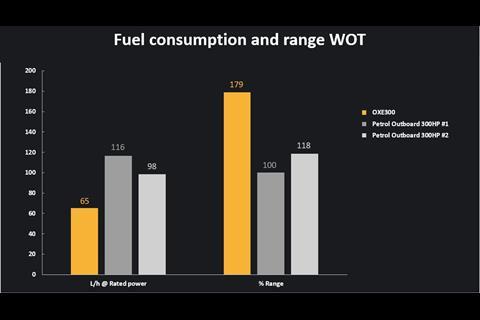

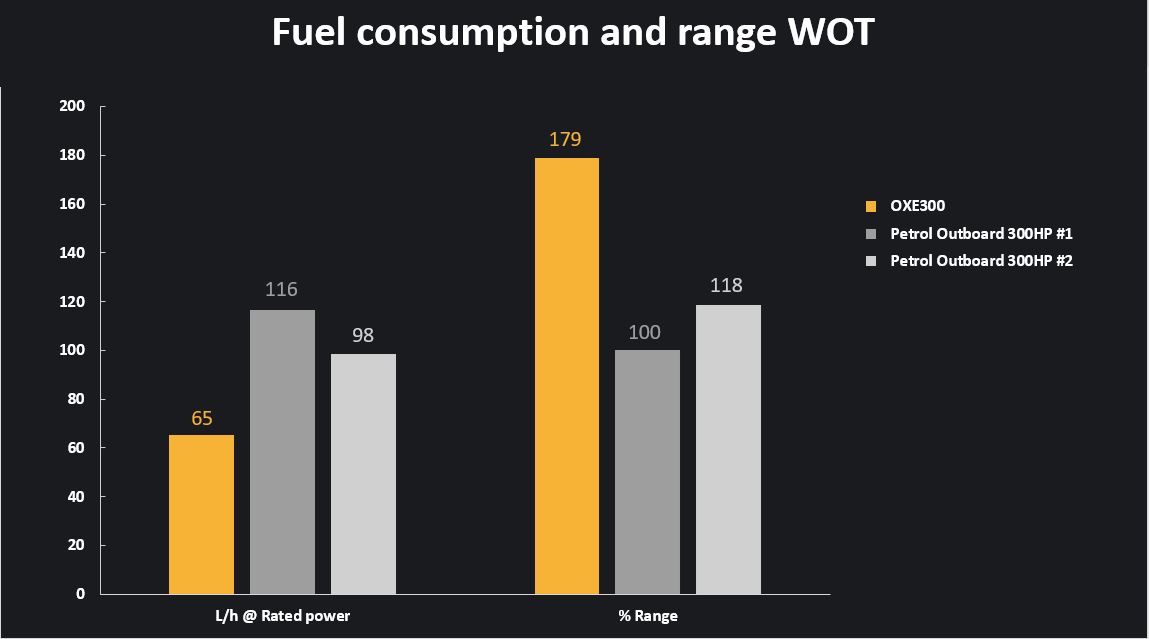

OXE 300 continues the fuel-efficient nature of the OXE Diesel range, consuming some 44% less fuel than a modern petrol outboard. It meets the latest emission standards and reduces carbon dioxide by more than 35%, carbon monoxide by more than 99% and combined hydrocarbons and NOx by more than 70%, compared to petrol outboard standards (EPA-Tier 3, RCD SI-Outboard and CARB 3 star).

The development of the 300HP version of OXE draws on the operative feedback from the 200 plus OXE Diesels in service. The range includes 125HP, 150HP, 175HP, 200HP and 300HP options to meet different user specifications.

The OXE Diesel is a cost-effective alternative to petrol in total cost of ownership, benefiting from lower fuel costs, higher working efficiency, lower maintenance and ease of sourcing compared to petrol. Diesel’s lower volatility also makes it a safer option than a petrol alternative.

TECHNICAL DATA - OXE300

|

Weight: |

395 kg |

|

Alternator output: |

180 Amp |

|

Rig length: |

25” or 33” |

|

Cooling: |

Closed cooling circuit |

|

Starting: |

Electric |

|

Steering: |

Electronic Power Steering |

|

Shiſt: |

CANbus, Electro-hydraulic |

|

Clutch: |

Hydraulic multi-friction plate |

|

Gear ratios: |

1.39:1 |

|

Dimensions (XL 25” leg/ XXL 33” leg), LHW |

XL, 1150x2090x700mm. XXL, 1150x2293x700mm (CC32”) |

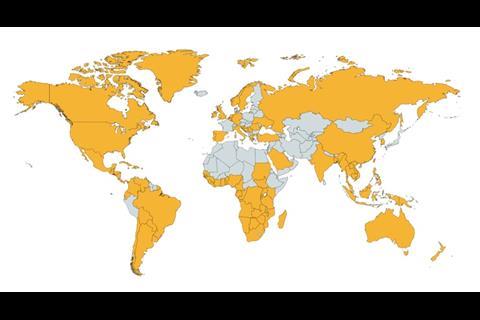

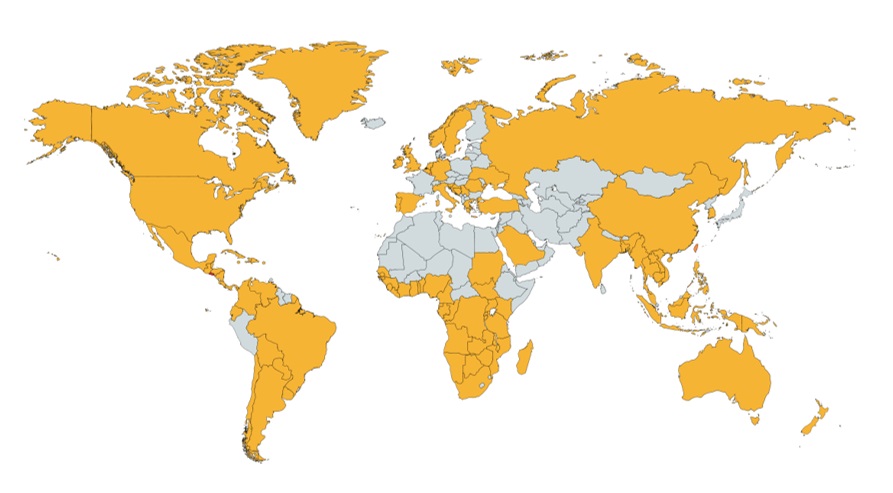

OXE Marine AB distributor network.

The sale of the Company’s outboard, OXE Diesel, is carried out through an established distributor network with approximately 24 distributors with over 200 OXE Diesel appointed dealers.

To find the distributor for your region, please visit:

PROTEUM

Proteum are a UK based marine distributor based in Southampton, providing marine diesel engines and support services to a worldwide customer base. Distributing a portfolio of marine products including, OXE Diesel, to both the commercial and pleasure boat markets. Proteum is the main UK and Ireland distributor for OXE Marine AB Diesel. Earlier this year the OXE 300HP Diesel began production, becoming the first 300HP diesel outboard available to UK and Ireland commercial marine users. OXE is the only range of high-performance diesel outboards in production and in service. Due to the pressures and new working guidelines following Covid-19, Proteum has still secured orders, commissioned engines and completed sea trails; keeping customers operational and ready to operate.