A new patented mechanical power transmission monitoring product range is proving to be the perfect solution for maintenance personnel and production planners alike.

It offers exceptional advantages for use within mechanical drivetrains that operate critical or non-critical processes and provides constant data about the condition of either gearboxes (AIQ CORE) or the elastomers within drive couplings (AIQ Detect).

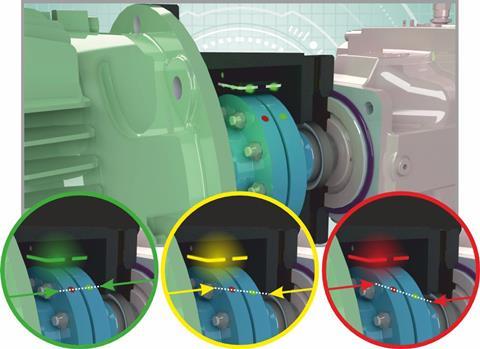

AIQ Detect monitors the position of the relevant coupling hubs to each other whilst the coupling is working in real time operation. Designed for use with the Flender N-EUPEX and RUPEX coupling ranges, the AIQ Detect indicates operating speed and elastomer wear both visually, using a traffic light system, green-light for good condition, yellow-light showing elastomer wear, or red-light indicating element requires replacing. Alternatively, it can transmit signals to a mobile phone, fitted with a license free AIQ application, via Bluetooth or can link to a PLC and will advise of healthy elastomer condition or can emit warning signals, or if required, shut down the process to avoid catastrophic damage.

A coupling modification kit can be supplied to enable existing couplings to benefit from the AIQ Detect.

Advantages in using the AIQ unit for coupling monitoring are:

- Continuous coupling elastomer wear monitoring, avoiding unexpected expensive downtime.

- Elimination of coupling failures

- Speed measurement.

- Direction of rotation detection.

- PLC connectivity to enable remote coupling condition monitoring.

- Coupling monitoring via blue tooth in conjunction with the AIQ mobile telephone app.

- Visual display of the condition of the coupling elastomers via built in led display.

- Optional Wi-Fi connectivity at point of order.

AIQ Core can be supplied pre-installed into Flender gearboxes or as a package of components that can be retrofitted into existing Flender units or for use within gearboxes supplied by other manufacturers (AIQ Core retro fit).

The AIQ core has been designed to monitor the condition of your gearbox continuously, 24 hours a day, 7 days a week and will provide data showing the condition of gears or bearings and in turn will advise not only if there is a problem, but it will also indicate which component is showing wear. Add to this the monitoring of fluid level, quality of oil and temperature and you truly have a device that is designed to save you unexpected down time, increase production and save money whilst increasing profitability.

The software will provide a digital output which can be monitored via Bluetooth, a PLC or via the dedicated AIQ web portal. Additionally, the unit can log operating times including stop / start information and will provide ID/Tag number information which will show the location of the equipment within the plant.

- Maintenance intervals can be planned based on the information provided by the AIQ Core.

- Up to 50% longer oil life.

- Lower service costs.

- Proactive maintenance can detect defects, reducing downtime.

- Connection via PLC, blue tooth, or Wi-Fi.

- A comprehensive AIQ App is available for both Android and IOS operating systems.

As you can see, the above advantages will give you peace of mind knowing that continuous condition monitoring of your gearboxes provides real time data which will enhance your maintenance programme decisions.

A typical application of the AIQ Detect & the technical capability of jbj Techniques Limited ~ exceptional mechanical & fluid power expertise.

jbj Techniques is a company with a wealth of experience in producing bespoke drivelines for critical applications and are regularly called upon to solve application problems both in industrial and hazardous environments.

An example of which led to the design and production of a special (now standard) assembly to work within the hydraulic industry and was developed for hazardous Zone 1 applications.

The development of the ‘Wet Mount Bellhousing assembly’ was to overcome an existing problem and enable the use of hydraulic piston pumps within a Zone 1 environment. The issue was down to the fact that when the pump was delivering various flow and pressure requirements for the system, the pulsation around the pump shaft seal would cause the seal to grip the shaft and consequently was generating excessively high temperatures which could produce a potential ignition source and so would not fall within the defined ATEX Zone 1 requirements.

Using existing jbj equipment and in-house manufacturing a suitable bellhousing assembly was created and with an additional cooling adaptor integrated onto the pump mounting face of the bellhousing, jbj were able to deliver an oil cooling path across the face of the pump shaft seal thereby reducing the temperature of the seal to within acceptable limits. The pumped oil flow was passed through an external heat exchanger to maintain the oil temperature. In addition a Rupex® drive coupling provided the connection between the motor and pump shaft and the assembly was provided complete with ATEX certification.